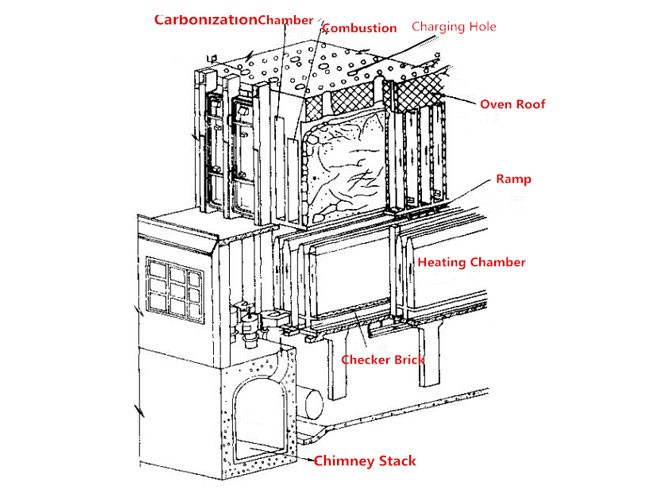

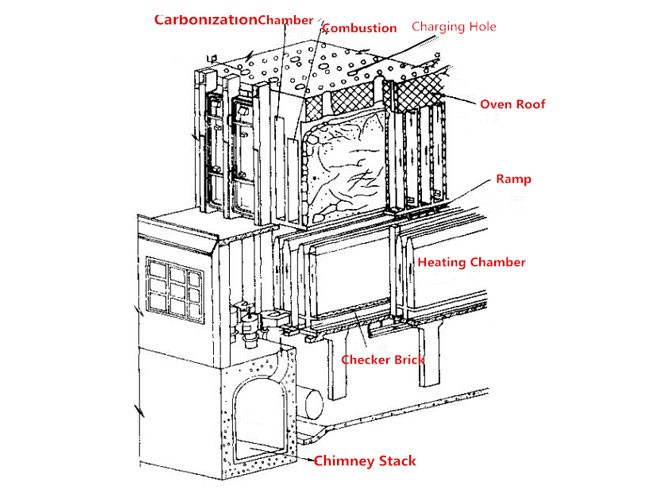

The coke oven is composed of carbonization chamber, combustion chamber, heat storage chamber, furnace roof, chute, small exhaust flue and basic positions. To build a 42-hole 58-I coke oven, about 6557t refractory and thermal insulation materials are needed, among which silica bricks are 4352t, accounting for 66.4%. In a coke oven operating cycle of 20 to 25 years, most of the masonry is not easy to repair. Therefore, the refractory and thermal insulation materials used in the furnace must be suitable for the regulations of the coking production process to achieve long-term safety and reliability.

The refractory and thermal insulation materials used for building coke ovens should have the following characteristics: the refractoriness under load of the materials is higher than the maximum ambient temperature of the application location; the materials can resist the corrosion of various substances encountered in the application location; the carbonization chamber and the combustion chamber wall have Excellent heat transfer performance;checker bricks have excellent heat storage characteristics and so on.